Counting Machine for OSD Forms

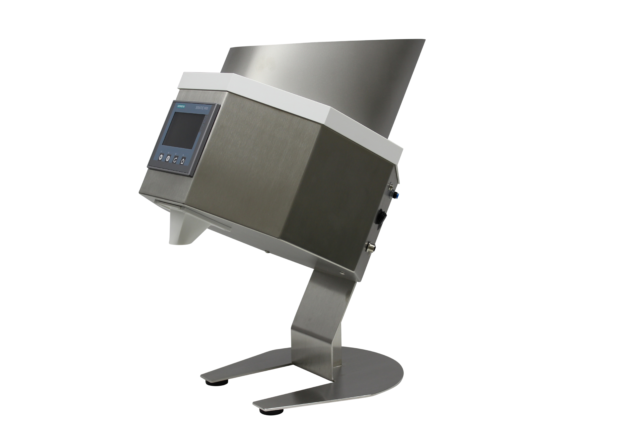

The professional GMP compliant counting and filling machine for tablets, capsules, dragees and other molded products in IP65 protection class.

Compact table unit for daily use in the pharmaceutical industry, pharmacy & contract manufacturing.

Often the filling and dosing by pure weighing is too imprecise to achieve consistent, optimal results. This counting system reachs almost 100% filling accuracy and reduce losses in your production process. Using the integrated inventory function you can do 100% check of incoming goods.

Technical Characteristics

| OSD Forms | hard gelatin capsules, soft gelatin capsules, tablets |

| Counting range | 1 – 99’999 |

| Speed | 57’000 / h |

| Ejection | filling funnel |

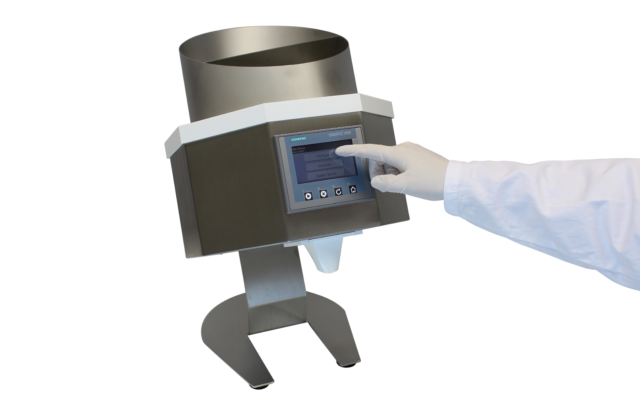

| Operation | Siemens S7 touchscreen (IP54) |

| Weight | approx. 19 kg |

| Size | 580 x 500 x 400mm |

Counting functions

Filling – Counting up to selected number of units (number of containers to be filled and number of objects per container freely adjustable) or incoming goods inspection – counting until emptying of the storage container

The device is operated via the intuitive touchscreen interface.

Cleaning

The machine has a built-in cleaning unit which can optionally be switched on. This is connected to a compressed air connection (clean, dry and oil-free pharmaceutical air, inlet pressure 1-5 bar). We recommend cleaning for very dusty products.

Housing & storage container executed in stainless steel and aluminum DURIN-COAT® FDA-proof coated, format discs in PET.

Flexibility

Whether you have tablets, capsules or pills to process – with the easy changeable format disk it is possible to process virtually any dosage form precisely on the machine. For all standard products such as capsules and tablets format discs are available from stock.

For special solutions and other products we manufacture these usually with no extra cost for you.

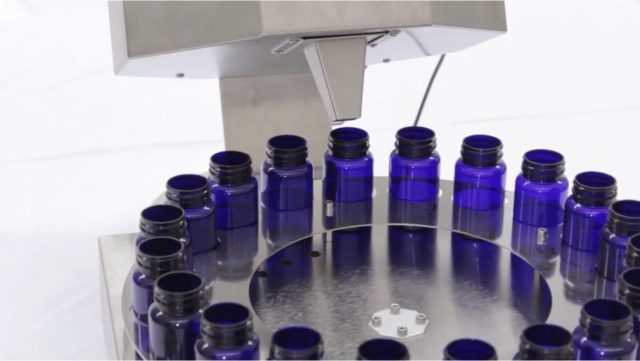

Automatic filling station

Fully automatic filling system as additional module. Depending on the bottle / container size, up to 32 containers can be filled in one go via the filling module. The system is simply connected to the I / O port of the machine and is ready to use.

The filling module can be adjusted to different container heights via the height-adjustable machine feet.